TEL:

13430627966

All Products

产品介绍

CF-150+ Extreme Corrosion Resistant Powder Electronic Coating

Basically represents the highest level of anti-corrosion

Product characteristics of CF-150+ corrosion resistant coatings

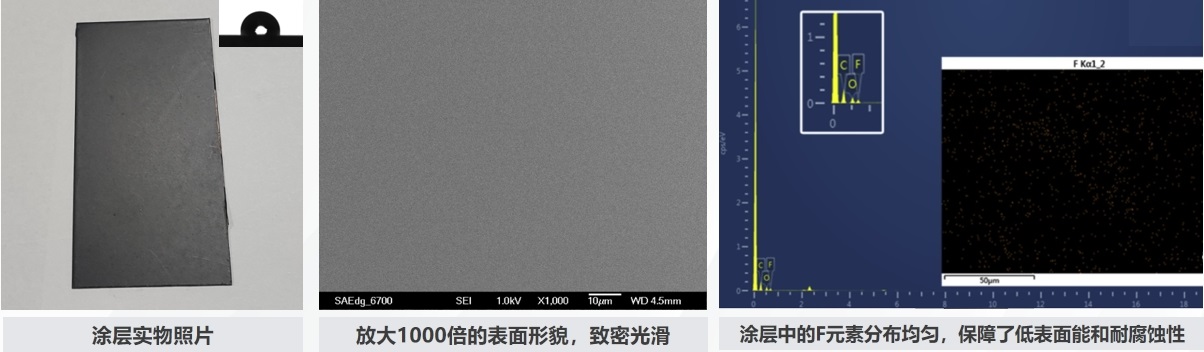

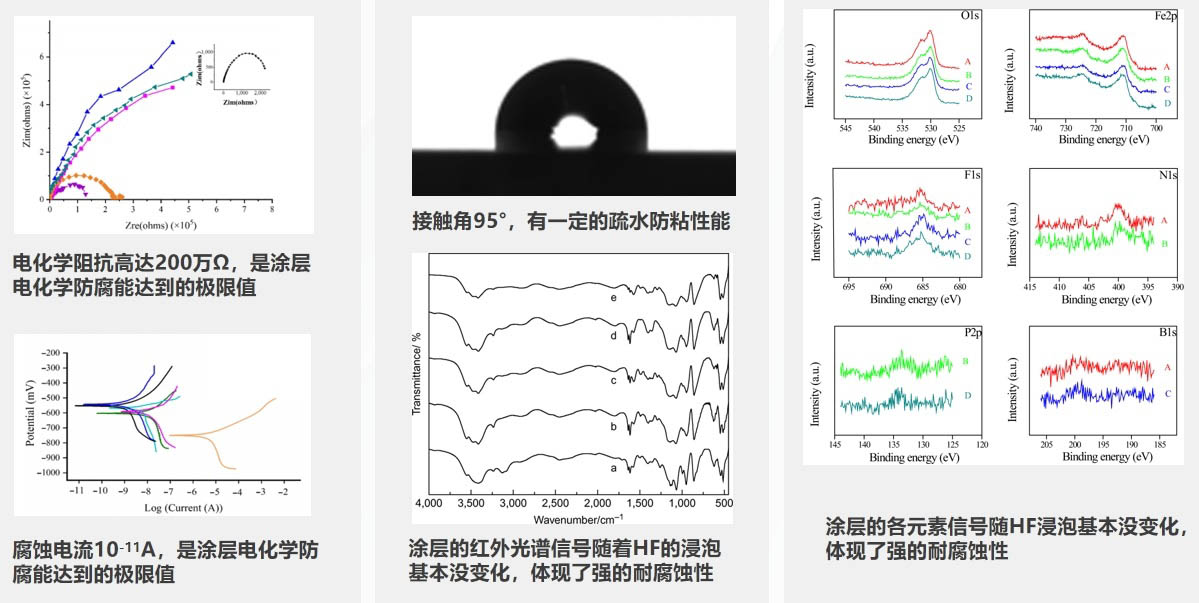

CF-150+ is a melt-processable fluorine-containing powder coating, which can be used for a long time under 150℃. It has excellent chemical resistance, low permeability, excellent weatherability and good wear resistance, and has excellent protection against strong acids, alkalis and oxidizers, basically representing the highest level of anticorrosion.

Basic parameters of CF-150+ corrosion resistant coating

Appearance: black powder

Melting point: 216-224 °C

Density: 1.68 g/L

Adhesion: Grade 0

Maximum continuous use temperature: 150 °C (according to UL)

Broad chemical resistance (pH 1-14)

Optimal combination of thermal, chemical and electrical properties

CF-150+ Corrosion Resistant Coating Construction Method (see TDS for details)

(1) Pre-treatment of metal substrate by sand blasting: Rust and other oxides should be completely abraded away, 16 mesh aluminum oxide or silicon carbide can be used for sand blasting.

Silicon oxide or silicon carbide can be used for sand blasting, and it is recommended that the minimum depth of the surface profile should be 0.05 mm;

(2) Pre-heating of metal parts: In spraying coatings, metal parts need to be properly pre-heated to 260-270℃;

(3) electrostatic spraying: use the appropriate electrostatic spray gun, in the hot parts of the surface uniform spraying, it is recommended to use the voltage can be adjusted negative electrostatic gun for KFL-0006 powder coating, usually the voltage in the 80-100kV, through a spray can be achieved 50-100μm.

4) Baking and curing: At a temperature of 250±10℃, good adhesion is obtained through sufficient baking, the baking time is determined by the thickness of the part and the baking temperature.

Extreme corrosion resistant powder coating (CF-150+)

No change in the appearance of the coating after immersion in 2% HF at 90°C for 200h

Coating immersed in 18% HCl solution at 90°C for 500h without any change

Eight advantages of the superhydrophobic coating of the new superprotective material: excellent water resistance, excellent short-circuit resistance, excellent corrosion resistance, natural self-cleaning, good heat dissipation, excellent anti-bacterial properties, excellent anti-condensation properties, and excellent anti-frosting/freezing properties.