TEL:

13430627966

Product Advantages

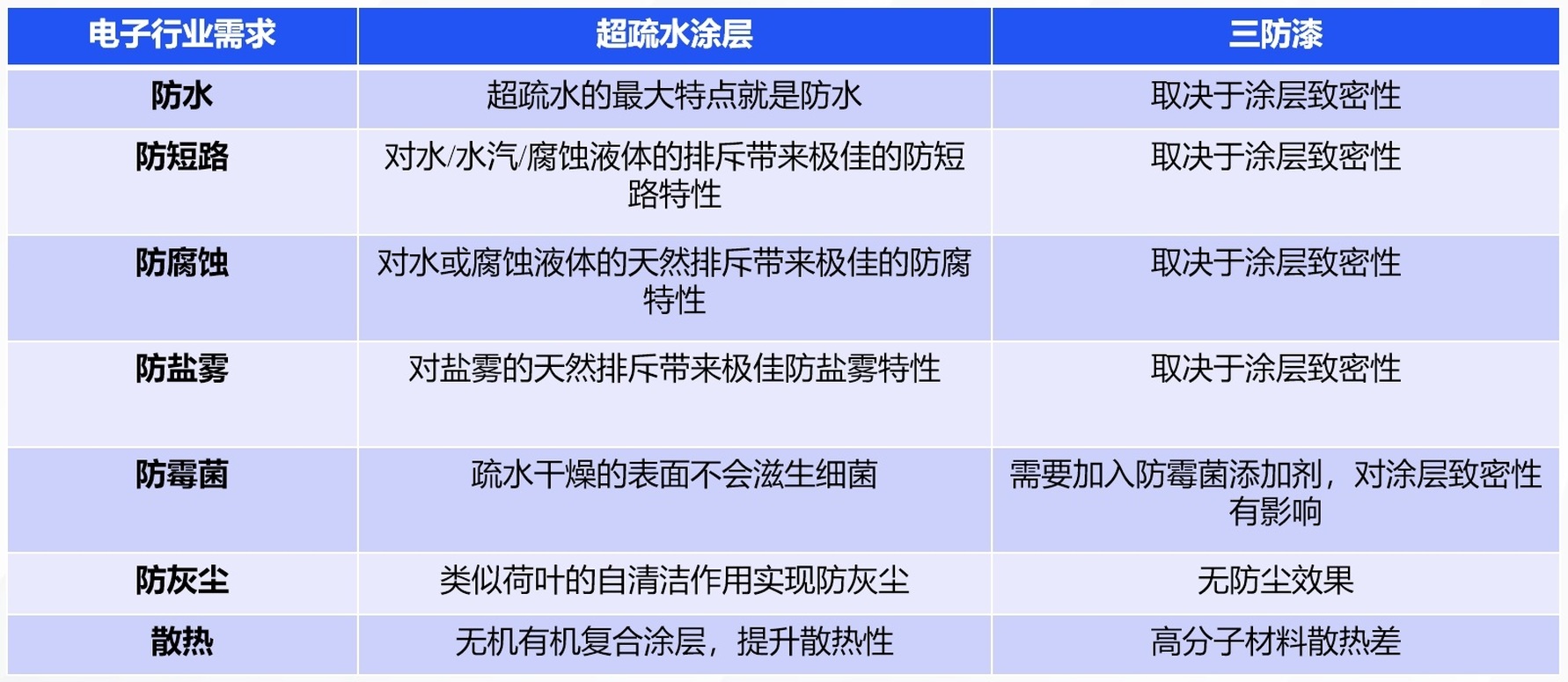

Comparison and Introduction of Superhydrophobic Coating and Triple Defense Paint

The protective performance of three-proof paint depends largely on the denseness of the coating, which is the focus of the three-proof paint manufacturers' efforts to research and development, and the superhydrophobic coating has an inherent natural waterproof, short-circuit-proof, corrosion-resistant, anti-salt spray, anti-mildew, anti-dust and other characteristics. Therefore: superhydrophobic materials can solve the pain point problem that three-proof paint can not solve!

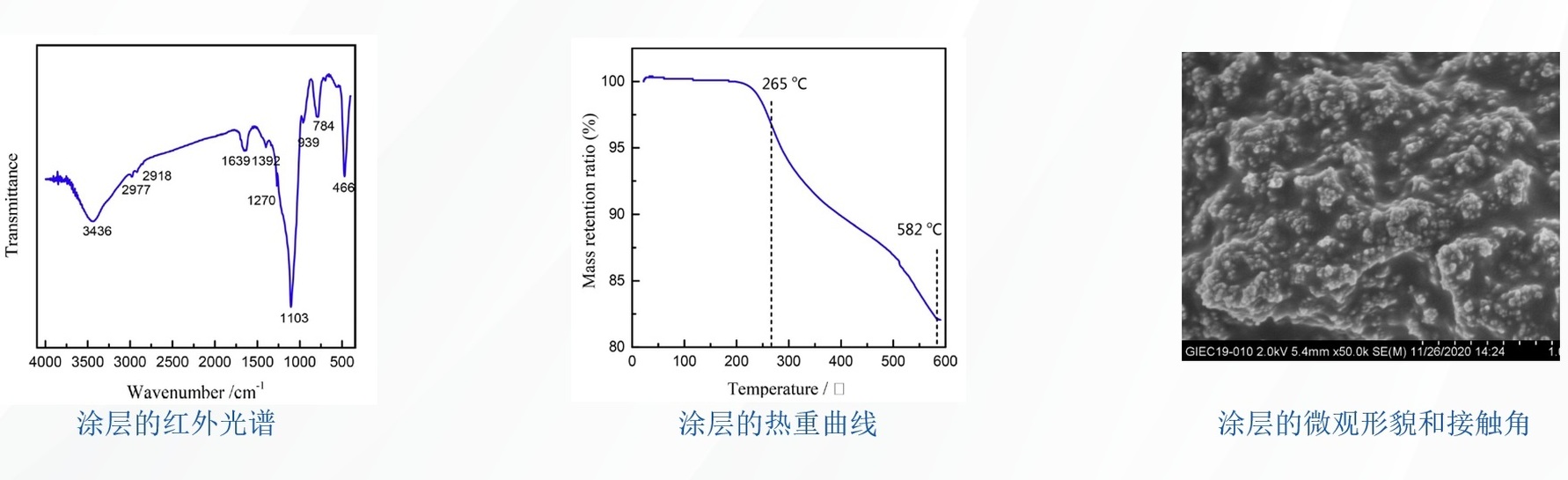

Basic Characterization of Ultra-Protective New Material Coatings

Basic Characterization of Ultra-Protective New Material Coatings

The thermal decomposition temperature of the coating is 265°C, which meets almost all the requirements for use in the electronics industry. The microstructure of the coating is highly compatible with the microstructure of the lotus leaf, showing a high contact angle of 163°.

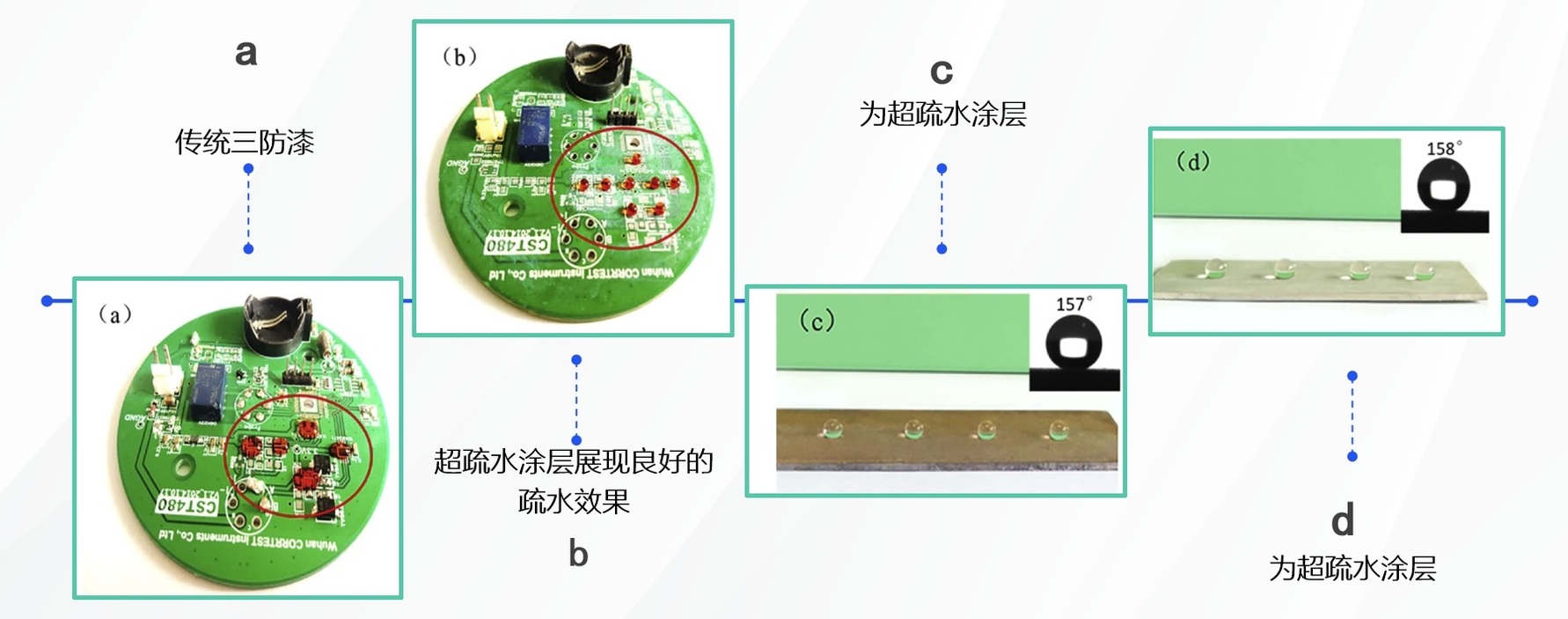

The hydrophobicity of superhydrophobic coatings applied on copper and tin plates with contact angles of 157 ° and 158°, respectively.

The hydrophobicity of superhydrophobic coatings applied on copper and tin plates with contact angles of 157 ° and 158°, respectively.

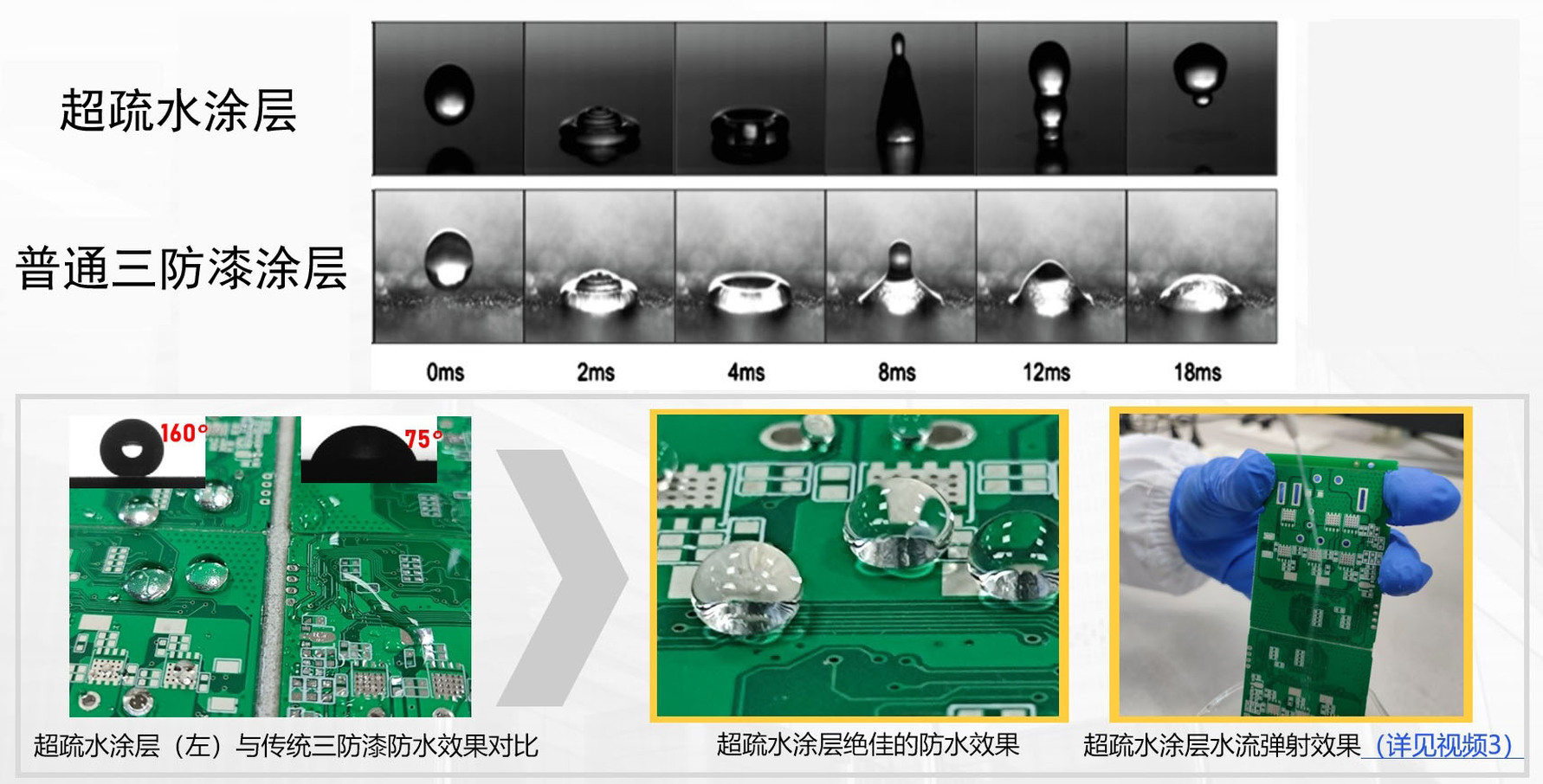

Comparison of contact angles between superhydrophobic coatings and conventional triple-proof paints

① Superhydrophobic coating for excellent water resistance

Super Hydrophobic Coating: Water droplet bouncing observed under high-speed camera, demonstrating excellent waterproof characteristics.

Ordinary Triple Defense Coating: No water droplet bouncing, average waterproof effect.

② Excellent short-circuit proof characteristics

② Excellent short-circuit proof characteristics

Reason analysis: Traditional three-proof paint is instantly infiltrated by salt water, resulting in short circuits. PCB boards coated with super-hydrophobic coating form a waterproof air layer when they are immersed in water, preventing water from seeping in, so they have excellent short-circuit performance.

Huawei's test results: our superhydrophobic coating's short-circuit prevention capability is 1.5 times that of 3M's triple-proof paint (salt spray method test).

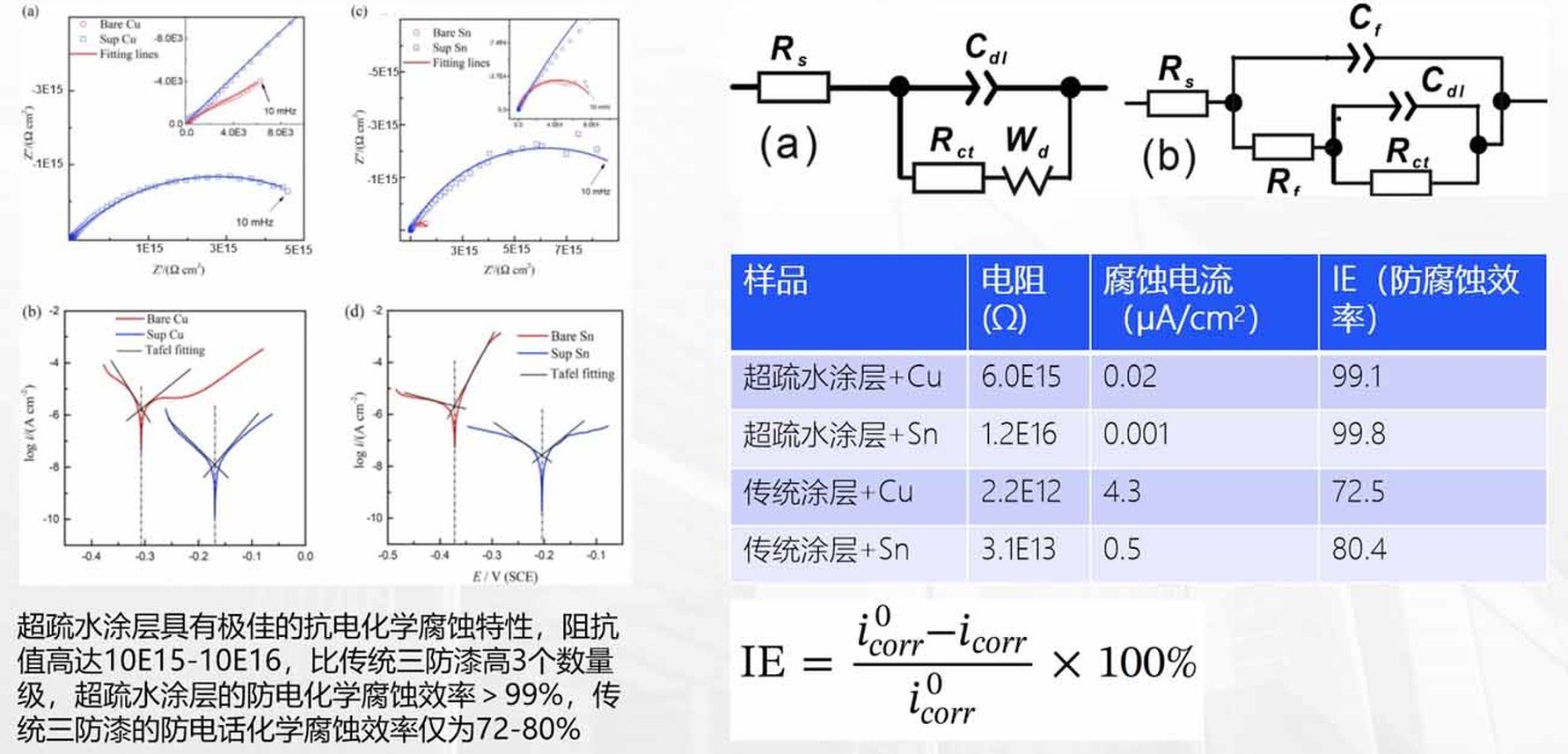

③ Excellent corrosion protection

③ Excellent corrosion protection

Superhydrophobic coating has excellent electrochemical corrosion resistance, the impedance value is as high as 10E15-10E16, which is 3 orders of magnitude higher than that of the traditional three-proof paint, and the efficiency of superhydrophobic coating against electrochemical corrosion is >99%, while that of the traditional three-proof paint against tele-chemical corrosion is only 72-80%.

④ Naturally self-cleaning

④ Naturally self-cleaning

Self-cleaning effect of superhydrophobic coatings applied to copper and tin plates, dust can be easily removed

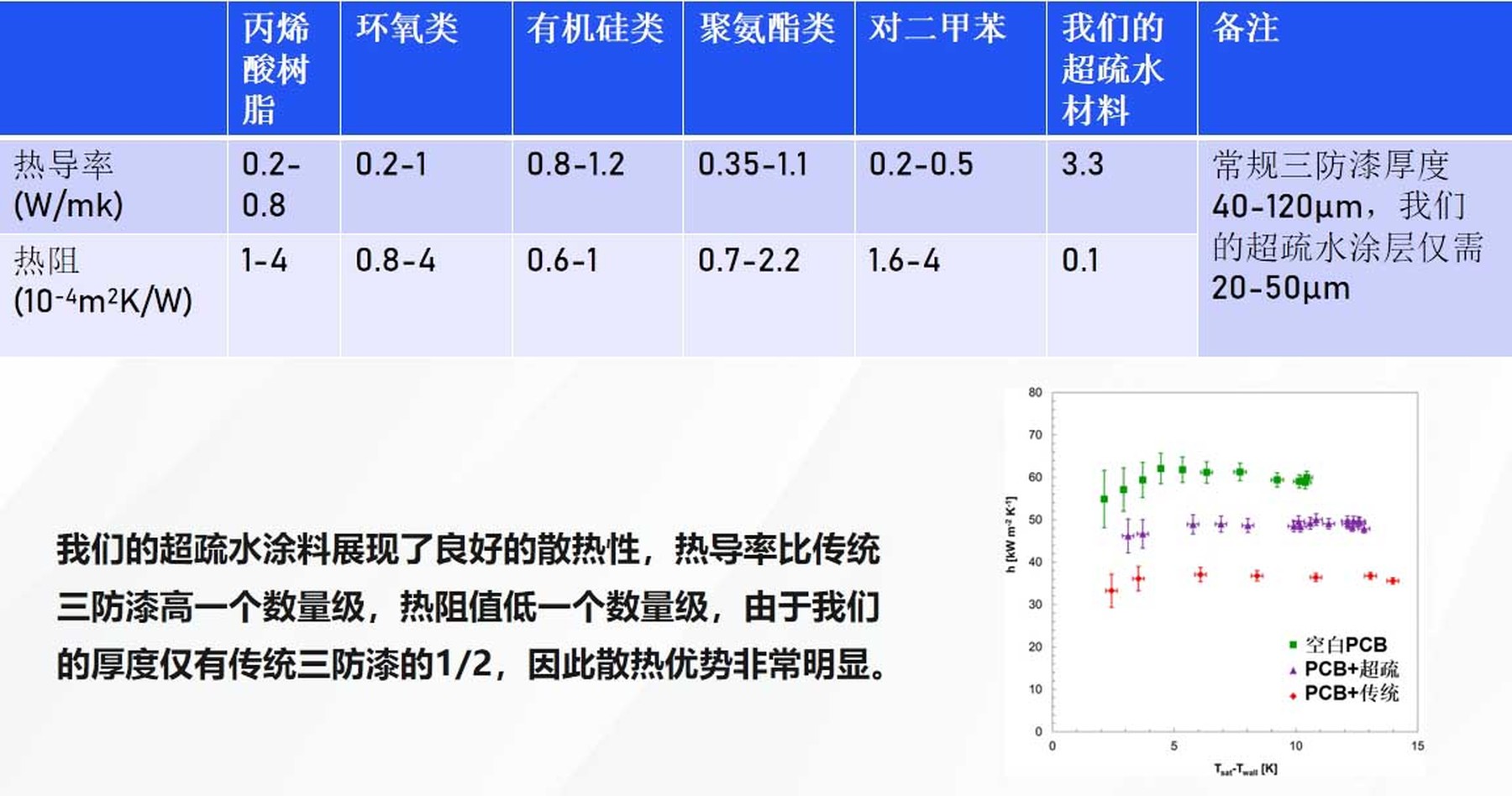

⑤ Good heat dissipation

⑤ Good heat dissipation

Our superhydrophobic coatings exhibit excellent heat dissipation, with thermal conductivity an order of magnitude higher and thermal resistance an order of magnitude lower than traditional triple-proof paints, and since our thickness is only 1/2 that of traditional triple-proof paints, the heat dissipation advantage is significant.

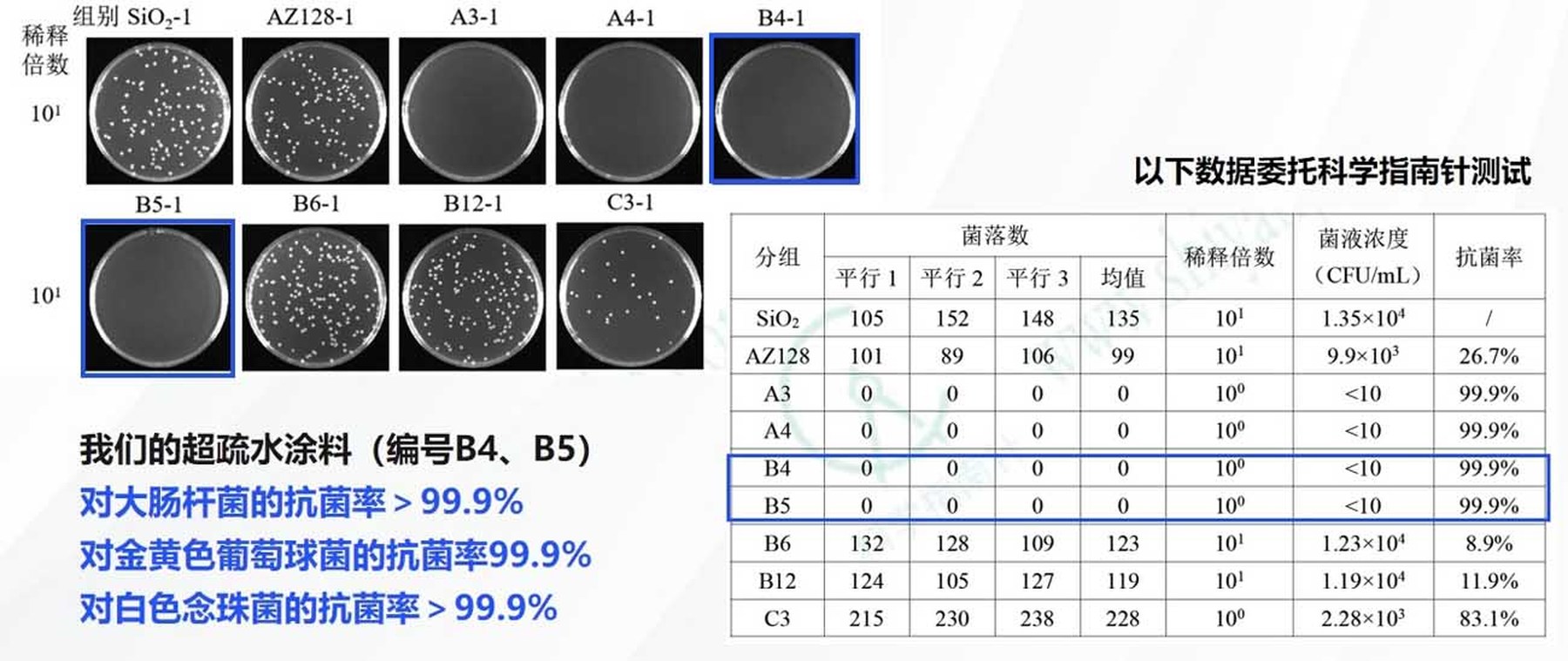

⑥ Excellent bacteriostatic properties

Our superhydrophobic coatings have an antimicrobial rate of >99.9% against E. coli, 99.9% against Staphylococcus aureus and >99.9% against Candida albicans.

⑦ Excellent anti-condensation properties

⑦ Excellent anti-condensation properties

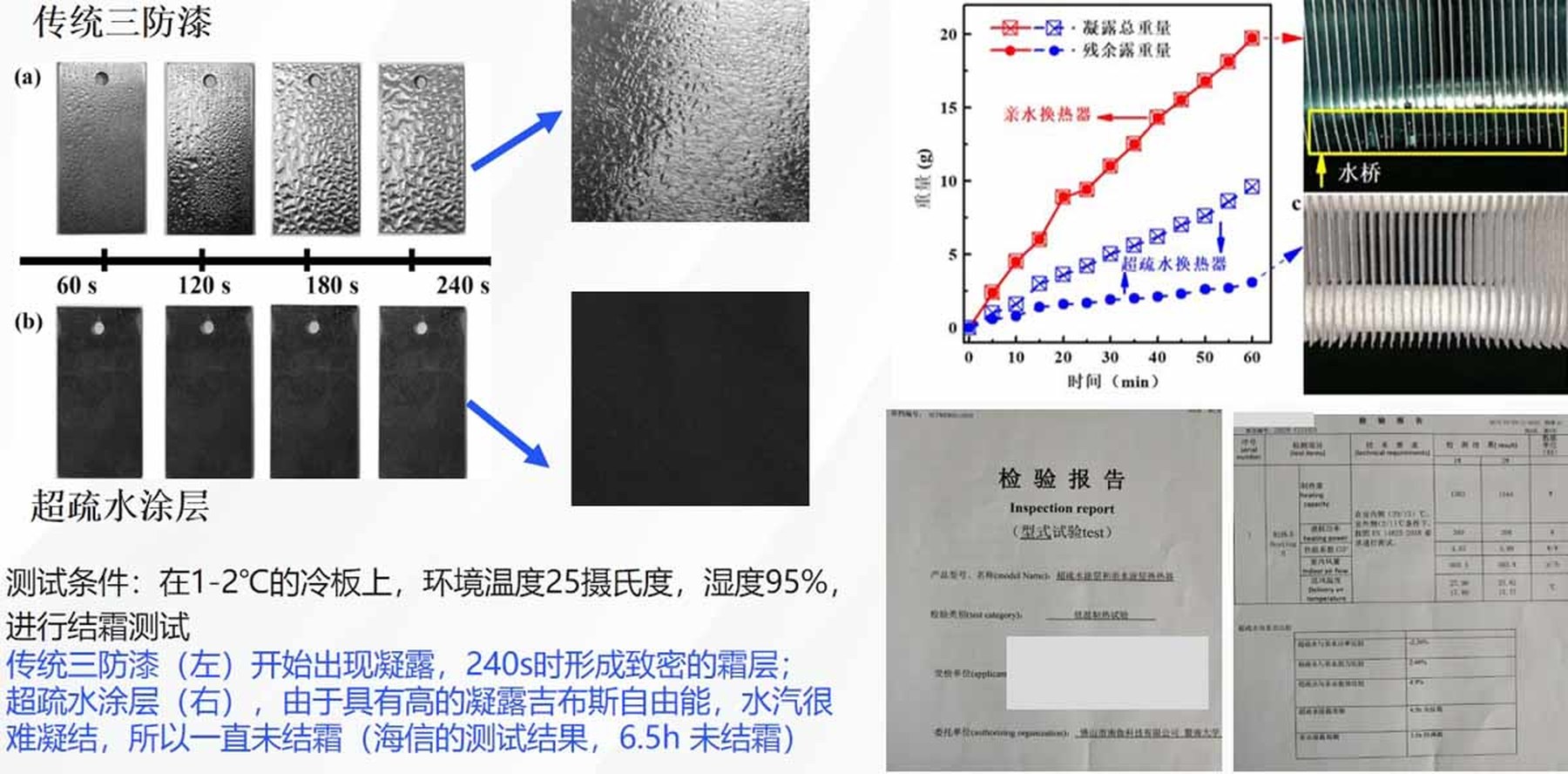

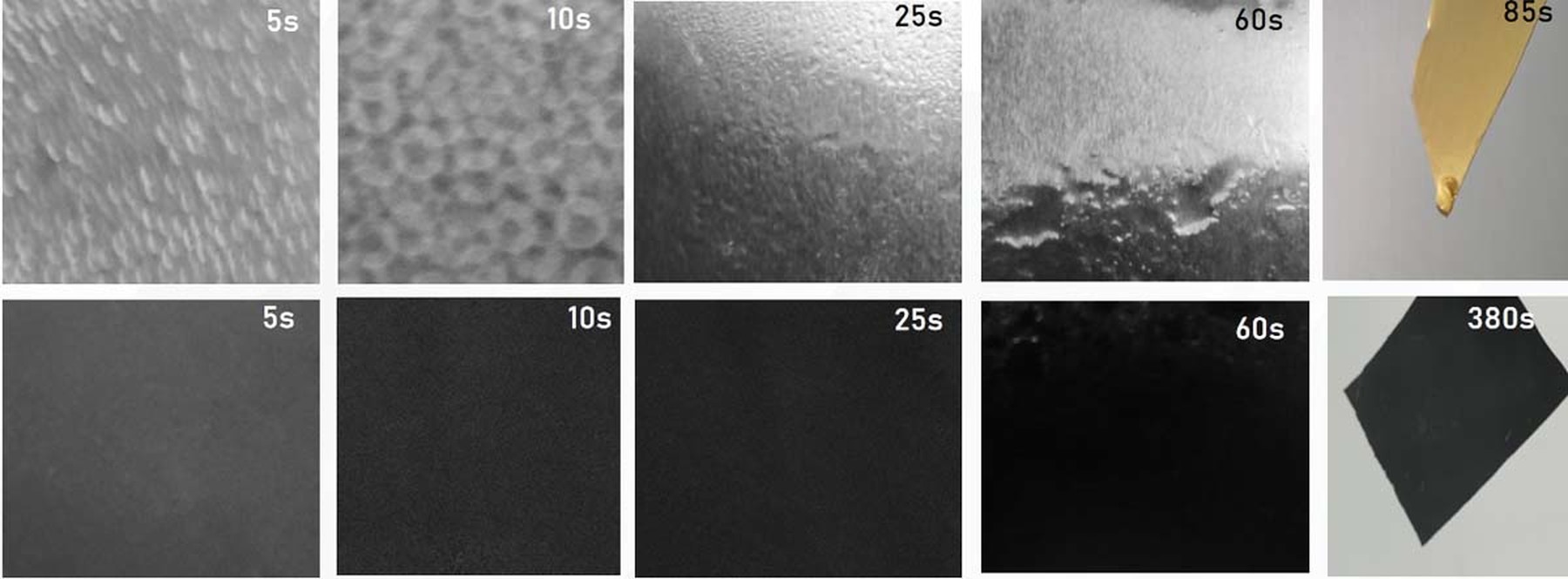

Test conditions: condensation test on a cold plate at 1-2°C, ambient temperature 25°C, humidity 95% Conventional three-proof paint (top) starts to condense at 5 seconds, water film visible at 25s, and dripping dew at 85s; superhydrophobic coatings (bottom), due to the high free energy of condensation Gibbs, it is very difficult for water vapor to condense, showing good anti-condensation characteristics.

⑧ Excellent anti-frosting/anti-icing properties

⑧ Excellent anti-frosting/anti-icing properties

Test conditions: Frost test on a cold plate at 1-2°C, ambient temperature of 25°C and humidity of 95% Conventional three-proof paint (left) started to condense, and a dense frost layer was formed in 240s; superhydrophobic coating (right), due to the high free energy of condensation Gibbs, it is difficult for the water vapor to condense, so it has not been frosted (Hisense's test result, no frost in 6.5h).